Thermoforming

Thermoforming vacuum technology is used in interior trim, exterior trim and underbody product design with different polymers and a wide range of color and pattern options. All products can be covered with different surface coating materials such as fabric, leather, TPU, depending on demand, and if necessary, various NVH materials can be mounted.

Interior trim parts are the first visual and tactile parts that the driver and passengers encounter in the living space offered inside the vehicle. We develop and produce stylish and quality products that meet expectations in order to make the living space in the vehicle the most beautiful. Mounting surface design is important for interior trim parts produced with thermoforming vacuum technology. We transfer our experience to the products regarding the selection, design and application of the metal and plastic brackets to be used.

We apply ultrasonic welding and bonding processes and all kinds of auxiliary equipment such as brackets, sponges, pads, felts to the products in the highest quality.

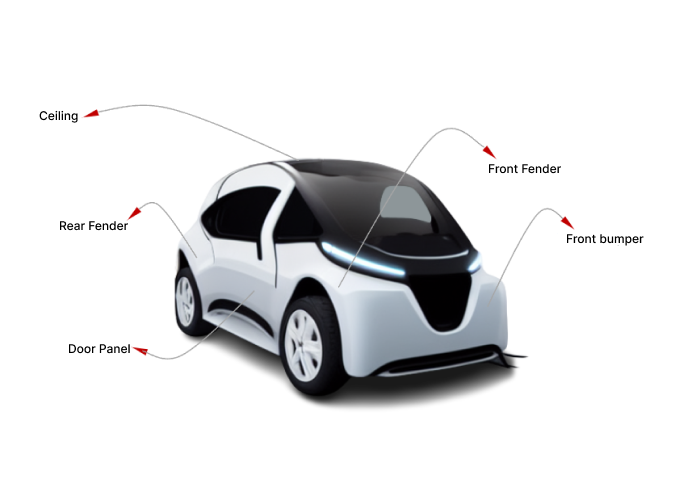

IP (Front Console), Door Panels, Side Panel Covering, Column, Partition, Seat Back, Wheel Inner and Outer Hoods, Loading Area Floor Covering, Engine Top and Bottom Covering are some of the interior trim product groups we produce with thermoform technology.

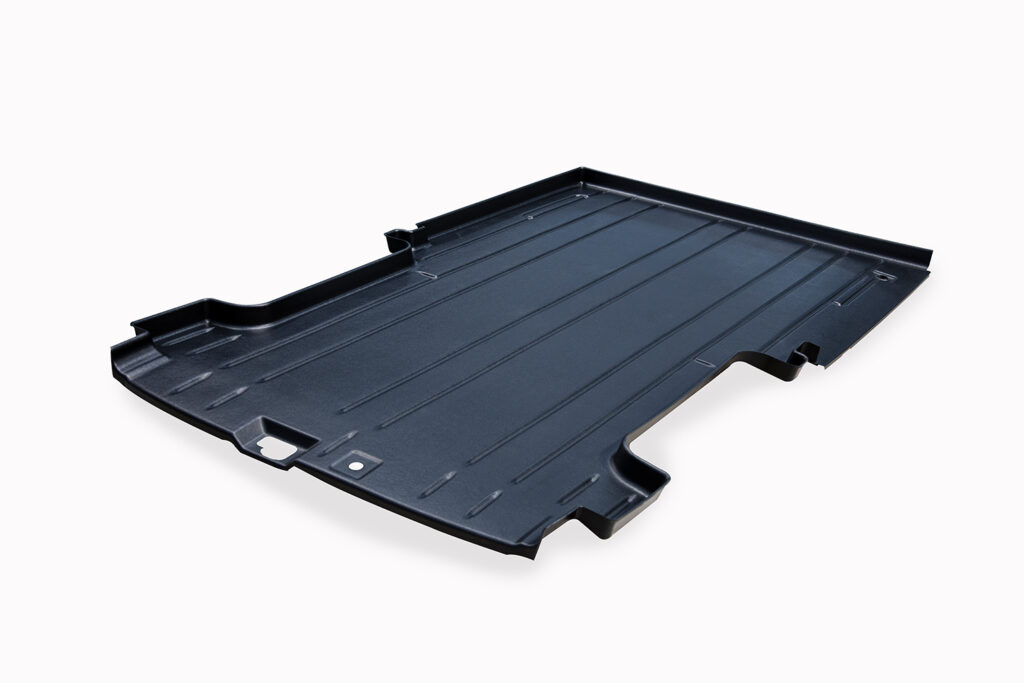

Loadliner

It is a part used in the floor covering of the cargo compartment in van type vehicles. Thermoforming process is used as the production technique and HDPE (high density polyethylene) is used as the material. A single piece with dimensions of 2.8 m x 4.4 m can be formed.

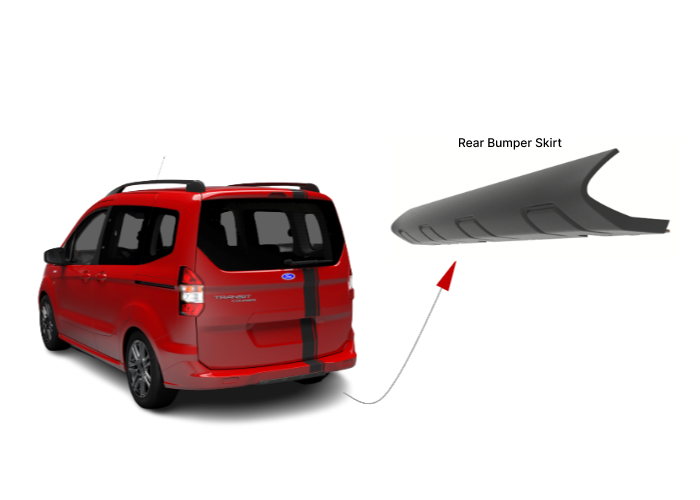

The other main product group we produce with thermoforming vacuum technology is exterior trim parts. We produce UV-resistant, self-colored exterior trim covering parts, especially for L-class vehicles, and provide services in engineering, design and testing, including project or product-based material selection. While we can be involved in the entire design development work, we also provide assembly design support only for B surfaces.

Exterior Trim Product Features

- Self-Colored, UV Resistant and Does Not Require Painting

- GLASS Supported High Quality Cutting

- Strong Mechanical Properties and Surface Scratch Resistance

- High Capacity with Multicavity Molding

Dış Trim Ürün Özellikleri

- Kendinden Renkli UV Dirençli ve Boya Gerektirmez

- CAM Destekli Yüksek Kalite Kesim

- Güçlü Mekanik Özellikler ve Yüzey Çizilme Direnci

- Çok Gözlü Kalıplama ile Yüksek Kapasite

Termoform vakum teknolojisi ile ürettiğimiz diğer ana ürün grubu ise dış trim parçalardır. Özellikle L sınıfı araçlar için UV dayanımlı kendinden renkli dış trim kapama parçalar üretmekte, proje veya ürün bazlı malzeme seçimi dahil mühendislik, tasarım ve test konularında hizmetler vermekteyiz. Geliştirme çalışmalarına tüm tasarım dahil olabileceğimiz gibi yalnızca B yüzeyleri için montaj tasarım desteği de vermekteyiz.