Composite

Reasons such as the development of technology, increased awareness, lower fuel consumption and therefore carbon footprint have led manufacturers to make lighter vehicles. In the recent period when the transition to electric vehicles has accelerated, high-performance lightweight products have become a necessity. We are proud to have developed new products every year and presented them to the manufacturer with the material knowledge and technology we have.

Developing high-strength and lighter parts is possible with composite technology. While doing this, we develop and produce fast and sustainable high quality composite products with our fully automatic forming and robotic cutting technology, without compromising mass production.

Some of the products we produce as composite: Partition, Headliner, Under Hood, Door Inner Panel, Hat Rack, Engine Lower Cover, Trunk Bottom Floor, Trunk Side Cover.

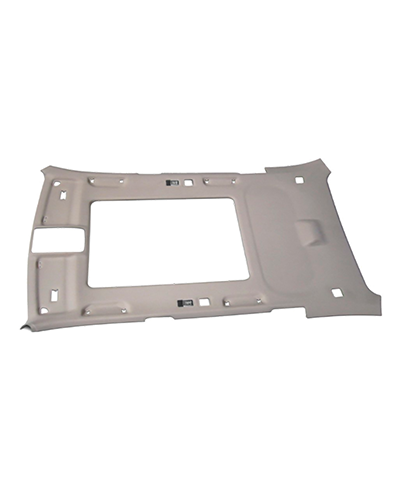

Composite Partition

It is the largest composite part used today in commercial and passenger vehicles. Ford Transit V363 model replaces the aluminum partition currently used in light commercial vehicles. Thanks to the unique layered structure of the product, it is strong enough to replace the metal part in the vehicle body. This part, which is used to separate the cargo and passenger compartments, shows a high level of performance in terms of both functionality and visuality.

2020 FORD

Excellence Award

Our Composite Partition product has been awarded with the « 2020 FORD Excellence Award » by FORD Motor Company.

Advantages over metal partition

- 30% weight reduction

- 25-35% cost advantage

- High NVH character

- Aesthetic appearance (Fabric covered and Soft-touch)